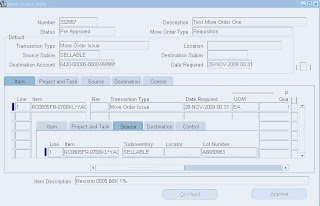

R12 - INV - Sample Script to Transact Move Order Using

INV_PICK_WAVE_PICK_CONFIRM_PUB API

DECLARE

l_api_version NUMBER := 1.0;

l_init_msg_list VARCHAR2 (2) := fnd_api.g_true;

l_commit VARCHAR2 (2) := fnd_api.g_false;

x_return_status VARCHAR2 (2);

x_msg_count NUMBER := 0;

x_msg_data VARCHAR2 (255);

l_move_order_type NUMBER := 1;

l_transaction_mode NUMBER := 1;

l_trolin_tbl inv_move_order_pub.trolin_tbl_type;

l_mold_tbl inv_mo_line_detail_util.g_mmtt_tbl_type;

x_mmtt_tbl inv_mo_line_detail_util.g_mmtt_tbl_type;

x_trolin_tbl inv_move_order_pub.trolin_tbl_type;

l_transaction_date DATE := SYSDATE;

l_user_id NUMBER;

l_resp_id NUMBER;

l_appl_id NUMBER;

CURSOR c_mo_details IS

SELECT mtrh.header_id, mtrh.request_number, mtrh.move_order_type,

mtrh.organization_id, mtrl.line_id, mtrl.line_number,

mtrl.inventory_item_id, mtrl.lot_number, mtrl.quantity,

revision, mtrl.from_locator_id,

(SELECT DISTINCT operating_unit

FROM org_organization_definitions

WHERE organization_id = mtrh.organization_id) org_id

FROM mtl_txn_request_headers mtrh, mtl_txn_request_lines mtrl

WHERE mtrh.header_id = mtrl.header_id

AND mtrh.request_number = '332557'

AND mtrh.organization_id = 381;

BEGIN

SELECT user_id

INTO l_user_id

FROM fnd_user

WHERE user_name = 'A42485';

SELECT responsibility_id, application_id

INTO l_resp_id, l_appl_id

FROM fnd_responsibility_vl

WHERE responsibility_name = 'Inventory';

fnd_global.apps_initialize (l_user_id, l_resp_id, l_appl_id);

FOR i IN c_mo_details

LOOP

mo_global.set_policy_context ('S', i.org_id);

inv_globals.set_org_id (i.organization_id);

mo_global.init ('INV');

l_trolin_tbl (1).line_id := i.line_id;

-- call API to create move order header

DBMS_OUTPUT.put_line

('=======================================================');

DBMS_OUTPUT.put_line

('Calling INV_Pick_Wave_Pick_Confirm_PUB.Pick_Confirm API');

inv_pick_wave_pick_confirm_pub.pick_confirm

(p_api_version_number => l_api_version,

p_init_msg_list => l_init_msg_list,

p_commit => l_commit,

x_return_status => x_return_status,

x_msg_count => x_msg_count,

x_msg_data => x_msg_data,

p_move_order_type => i.move_order_type,

p_transaction_mode => l_transaction_mode,

p_trolin_tbl => l_trolin_tbl,

p_mold_tbl => l_mold_tbl,

x_mmtt_tbl => x_mmtt_tbl,

x_trolin_tbl => x_trolin_tbl,

p_transaction_date => l_transaction_date

);

DBMS_OUTPUT.put_line

('=======================================================');

DBMS_OUTPUT.put_line (x_return_status);

DBMS_OUTPUT.put_line (x_msg_data);

DBMS_OUTPUT.put_line (x_msg_count);

IF (x_return_status <> fnd_api.g_ret_sts_success)

THEN

DBMS_OUTPUT.put_line (x_msg_data);

END IF;

DBMS_OUTPUT.put_line

('=======================================================');

END LOOP;

EXCEPTION

WHEN OTHERS

THEN

DBMS_OUTPUT.put_line ('Exception Occured :');

DBMS_OUTPUT.put_line (SQLCODE ':' SQLERRM);

DBMS_OUTPUT.put_line

('=======================================================');

END;

DBMS Output:

=======================================================

Calling INV_Pick_Wave_Pick_Confirm_PUB.Pick_Confirm API

=======================================================

S

=======================================================

Verification:

select * from mtl_material_transactions_temp

where transaction_temp_id = 1094230

No Rows Returned

-- Link the Move Order with the Material Transcations Table

SELECT

mmt.transaction_id,

mtrl.organization_id,

mtrh.request_number,

mtrh.header_id,

mtrl.line_number,

mtrl.line_id,

mtrl.inventory_item_id,

mtrh.description,

mtrh.move_order_type,

mtrl.line_status,

(select meaning from mfg_lookups

where lookup_type = 'MTL_TXN_REQUEST_STATUS'

and lookup_code = mtrl.line_status) Line_status_meaning,

mtrl.quantity,

mtrl.quantity_delivered,

mmt.transaction_type_id,

mmt.transaction_date

FROM mtl_txn_request_headers mtrh,

mtl_txn_request_lines mtrl,

mtl_material_transactions mmt

WHERE mtrh.header_id = mtrl.header_id

AND mtrh.organization_id = mtrl.organization_id

AND mtrl.line_id = mmt.move_order_line_id

AND mtrh.request_number = 332557

AND mtrh.organization_id = 381